Technical Specifications

Kinema numerical control on PC base consisting of:

- Numerical Control on Personal Computer platforms entirely based on real time 32/64 bit software

- Advanced axis management with multi-channel interpolation, dynamic queueing movements, and linear, trapezoidal and simple ramps. Complete dynamic control of axis parameters and PLC integration

- Virtual axes and gantry axes with variable ratio on the fly

- Advanced interpolations, developed in differential kinematics, supporting natively a large number of machine types (pantographs, 5-axis machines, delta robots, …)

- Single, crossed and flat linearity correctors. Mechanical compensations

- Native ISO interpreter, fully customizable. All standard calls may be overloaded as well as defining personalized G/M/T codes

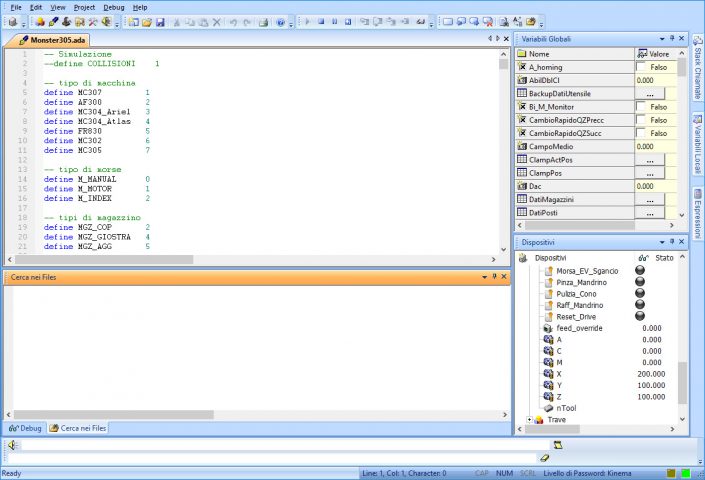

- Plc programming with high-level multitasking script language and real time debugger

- IEC1131 (ST) language support

- Advanced diagnostics with a 1-year event log without a limit to the number of records, realtime diagnostics, input/output status, integrated oscilloscope

- Event timeout management and dynamic messaging in function of machine status

- Remote assistance integrated in the system making it possible to analyze malfunctions and/or modify the PLC without requiring the presence of an operator

- Complete access for interfacing with external software. Personalized dashboards, serial drivers, barcode readers, production reports…